[Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system independently.

[Capacity]: 3-22T/h

[Improvement]: All important parts of raymond mill are made of high-quality steels, and all wear-resistant parts are made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

Force produced from milling roller connected by the pull rod and the high pressure spring can avoid damages caused by bulk materials to the equipment;

Resilient coupling between the main engine and separator can reduce the vibration and noise and improve the service life of equipment. Because of connecting crushing, drying, grinding, classifying and transmission together with the simple system and compact layout, it covers about 50% of the area of the ball mill system and can be outdoor arrangement, which can reduce the investment cost a lot;

Milling roller devices adopt superimposed multistage seal with excellent seal performance. Unique air circulation system with advanced dust remover carries the environmental protection concept through to the end;

Impeller devices with high density and high precision increase more than 50% of finished product yield under the same power. Efficient and energy-saving centrifugal induced draft fans improve the efficiency of induced draft fans greatly.Convenient impeller adjusting devices improve the precision of the finished product.

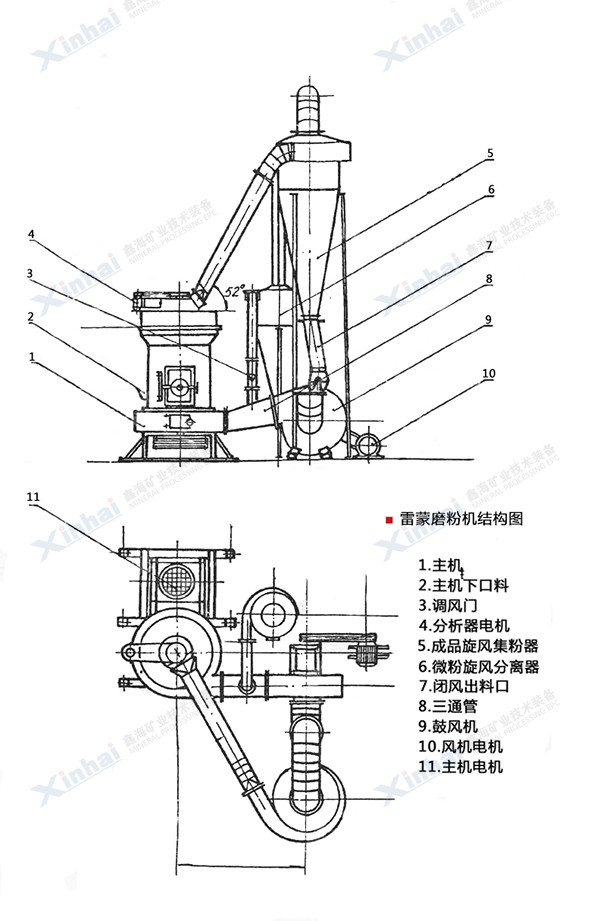

Large bulk materials crushed by thejaw crusher to the needed size are fed into the storage hopper by a mine hoist and then fed into a grinding chamber of main engine uniformly, quantitatively and continuously by a electromagnetic vibrating feeder for grinding. Grinded materials are blown into separator by blower for classification. With the function of impellers in the separator, materials without meeting the requirements of the fineness are fallen into a grinding chamber for grinding again; materials meeting the requirements of the fineness are blown into a cyclone powder collector with airflow through pipelines for separation and collection. The powder from a discharging device is the finished product. Separated airflow is back to blower through return duct on the top of the cyclone powder collector.

| Model | Max. Feed Size (mm) | Finished Product Size (mm) | Production Capacity (t/d) | Rotating Speed of Main Motor (r/min) | Main Motor Power (kw) | Milling Ring Diameter (mm) | Milling Ring Height (mm) | Milling Roller Diameter (mm) | Milling Roller Height (mm) | Milling Roller Qty. | Overall Dimension(m) (Length × Width × Height) |

| MTM75 | <15 | 0.613-0.033 | 1-3 | 160 | 18.5 | Inner Diameter 780 | 150 | 260 | 150 | 3 | 4.3×3.5×5.1 |

| MTM85 | <20 | 0.613-0.033 | 1.2-4.6 | 150 | 22 | Inner Diameter 830 | 140 | 270 | 140 | 3 | 5.3×4.1×5.2 |

| MTM100 | <25 | 0.613-0.033 | 2.1-5.6 | 130 | 37 | Inner Diameter 950 | 170 | 310 | 170 | 4 | 7.1×5.9×7.9 |

| MTM130 | <30 | 0.613-0.033 | 3-9.5 | 103 | 75 | Inner Diameter 1280 | 210 | 410 | 210 | 5 | 7.85×8×9.7 |

| MTM160 | <35 | 1.6-0.045 | 5-22 | 82 | 132 | Inner Diameter 1600 | 270 | 440 | 270 | 6 | 12.55×5.7×8.3 |