[Introduction]: A wet permanent magnetic separator for separating strong magnetic minerals

[Capacity]: 24t/h-240t/h

[Improvement]: Magnetic system materials adopt the NdFeB with high magnetic energy product and high coercivity, strong magnetic density and high affect depth; the surface of the cylinder is lined with Xinhai wear-resistant rubber.

Magnetic systems all adopt Nd-Fe-B magnets with high magnetic energy product and high coercivity, strong magnetic density and high affect depth. The demagnetization rate of the magnetic density within 8 years is no more than 5%.

The large wrap angle magnetic system with gradual field strength and smooth transition increases the length of the separation zone and the number of magnetic flips to achieve efficient separation of magnetic minerals and non- (weak) magnetic minerals;

Covering the magnetic system with non-magnetic stainless steel ensures no peeling off of the magnet.

According to different usage and processing conditions, the magnetic separators have different magnetic system design and tank structure.

The cylinder adopts non-magnetic stainless steel, covered with the super wear-resistant rubber produced by our company, thus the service life can be prolonged significantly

The permanent magnetic roller has a strong adaptability of production. It can bear large change of feeding amount, particle size and pulp concentration.

Good processing indexes such as high grade and high recovery rate can be acquired at the same time.

All the series of magnetic separators can be used cooperatively or singly. The good processing indexes can both be acquired.

Semi-countercurrent cell body. It can also be made as downstream body according to the processing condition and user requirements.

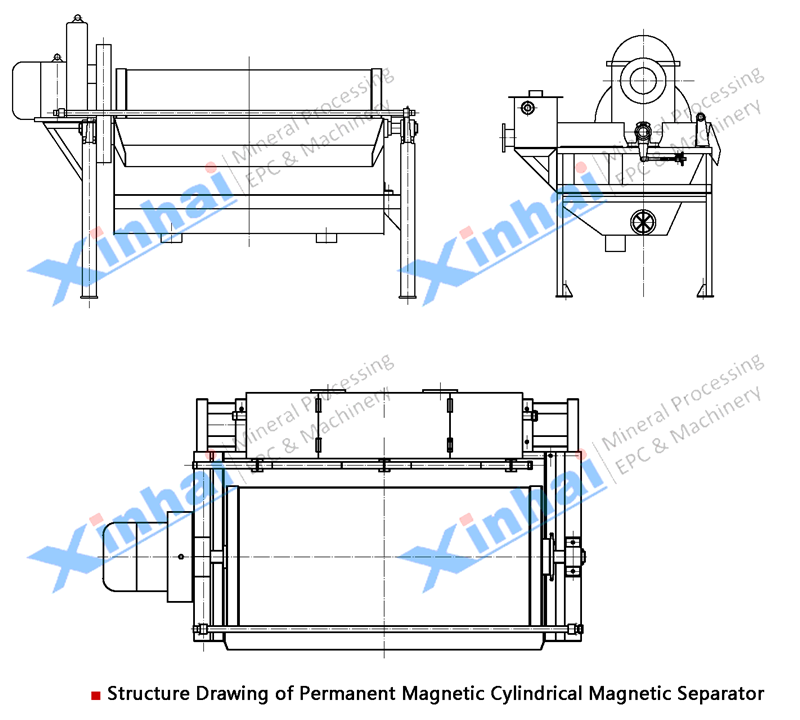

Permanent magnetic drum separators have 3 kinds including downstream type, counter flow type and semi- counter flow type according to the difference of base structures.

Downstream type permanent magnetic drum separator: slurry flows in the same direction with the drum.

Counter flow type permanent magnetic drum separator: slurry flows over against the drum, which create great conditions for cleaning of non magnetic ores. The non magnetic ores approach the clean surface of the drum and the magnetic ores can be absorbed in the strongest magnetic field.

Semi-counter flow type permanent magnetic drum separator: slurry is fed into the cavity from the bottom of the drum, and the magnetic ores fall into the concentrate tank after reaching a certain height, while the non magnetic ores will enter into tailings tank along with slurry in the opposite direction with drum.

| Model & Spec. | CTBY1018 | CTBY1024 | CTBY1030 | CTBY1218 | CTBY1224 | CTBY1230 |

| Diameter of Cylinder (mm) | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 |

| Length of Cylinder (mm) | 1800 | 2400 | 3000 | 1800 | 2400 | 3000 |

| Surface Magnetic Density (mt) | 350~550 | 350~550 | 350~550 | 350~550 | 350~550 | 350~550 |

| Rotating Speed of Cylinder (r/min) | 23 | 23 | 23 | 20 | 20 | 20 |

| Capacity of Dry Ore (t/h) | 42 ~65 | 53 ~86 | 82~124 | 58 ~97 | 71~120 | 103~158 |

| Feed Size (mm) | 0~10 | 0~10 | 0~10 | 0~10 | 0~10 | 0~10 |

| Slurry Density (%) | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 |

| Motor Power (kW) | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

| Total Weight (t) | 5.2 | 6.4 | 7.1 | 6.7 | 7.2 | 8.9 |

| Equipment Length (mm) | 3160 | 3790 | 4460 | 3380 | 4190 | 4770 |

| Equipment Width (mm) | 2250 | 2250 | 2250 | 2460 | 2460 | 2460 |

| Equipment Height (mm) | 1750 | 1750 | 1750 | 2000 | 2000 | 2000 |