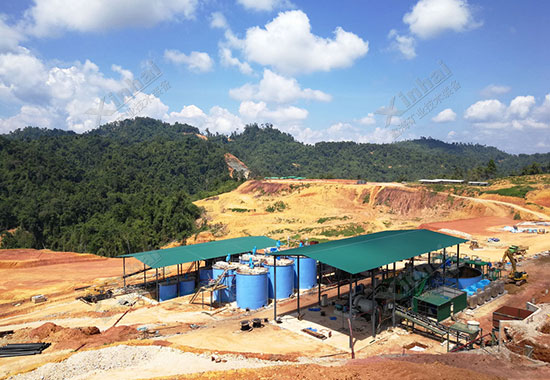

Malaysia boasts abundant mineral resources, but its mining equipment is insufficient to meet the beneficiation demands. It lacks the conditions to independently construct modern beneficiation plants due to inadequate mining management and beneficiation technology. With innovative beneficiation models, renowned brand recognition, and professional beneficiation technology, Xinhai Mining Equipment has become a vital choice for cooperation in Malaysia's mining development. The 700tpd gold mine CIL beneficiation plant in Malaysia is a microcosm of Sino-Malaysian mining development cooperation. Xinhai provided EPC+M+O services for this project.

Ore Characteristics: The ore mineral composition is relatively simple, with pyrite as the metallic mineral and quartz, calcite, mica, etc., as the non-metallic minerals. The original ore contains 4.70g/t of gold, 4.63g/t of silver, 20.10% of iron, and 20.55% of sulfur. The valuable elements available for recovery are gold.

Process Flow: Two-stage closed-circuit grinding → pre-leaching thickening → leaching adsorption → tailings dry stacking.

According to the project contract, Xinhai Mining Equipment provided a full industry chain service (EPCM+O) for the 700t/d gold mine CIL beneficiation plant in Malaysia, including beneficiation tests, mine design, equipment manufacturing and procurement, packaging and shipping, installation and commissioning, worker training, achieving standard production, mining management, and operation.

E: Design and Research Services

Xinhai conducted beneficiation tests, determined the ore properties, and explored the beneficiation process conditions. After discussions with the client, Xinhai decided to adopt a two-stage closed-circuit grinding classification in the grinding stage. The ground products were screened by a dewatering screen, and the undersize flowed to the concentrator for concentration. The bottom flow of the concentrator was pumped to the leaching operation. After leaching, adsorption, and carbon stripping, gold-loaded carbon products were obtained and transported to the existing gold extraction plant for processing. The leaching tailings were dehydrated by a filter press, and the recycled water was reused. The dry tailings were transported to the tailings pond for storage. In terms of mine design, Xinhai Mining Equipment dispatched technical experts to conduct on-site investigations of ore resources, surrounding terrain, water sources, power supply, etc. Based on the beneficiation test results, a process flow and equipment selection design construction drawing were proposed, providing professional planning for the beneficiation plant.

P: Complete Equipment Manufacturing and Procurement

According to the equipment selection requirements of the "700t/d Gold Mine Beneficiation Test Report in Malaysia," Xinhai Mining Equipment tailored a complete set of main and auxiliary equipment. Technical improvements were made to the existing equipment to integrate it with the process. The entire production process of the beneficiation plant realized mechanized operation, and some key operations or positions achieved automatic control. After the completion of equipment manufacturing and procurement, all equipment was delivered intact to the project site through a comprehensive packaging and shipping management system.

C: Debugging and Delivery

During the installation and commissioning phase, Xinhai Mining Equipment dispatched experienced installation and commissioning teams to the beneficiation plant site. They fully participated in the installation and commissioning work and provided professional maintenance and training services. All installation and commissioning work was completed in about one month, with the process debugging indicators passing at once and the project being 100% qualified upon acceptance.

M: Mine Management

In terms of mine management and operation, Xinhai Mining Equipment provided professional technical services guidance for civil construction, steel structure construction, tailings treatment, and tailings pond engineering design. In addition, Xinhai Mining Equipment conducted multiple follow-up visits to ensure that the beneficiation plant met the recovery rate standards, the product quality was guaranteed, and the process equipment operated stably.

O: Mine Operation

The Malaysia 700t/d gold mine CIL beneficiation plant achieved formal production in just six months. The expected design processing capacity was 600t/d, and the actual processing capacity reached 700t/d. The expected gold recovery rate was 93%, while the actual recovery rate was 95%. The beneficiation plant's profits were considerable.

Xinhai Mining Equipment's mining services have covered more than 100 countries and regions worldwide. In the future, Xinhai Mining Equipment will continue to promote its innovative development, further improve beneficiation processes and equipment, deepen its international market strategy, and provide customers with more comprehensive, professional, and on-site full-industry chain services (EPCM+O).