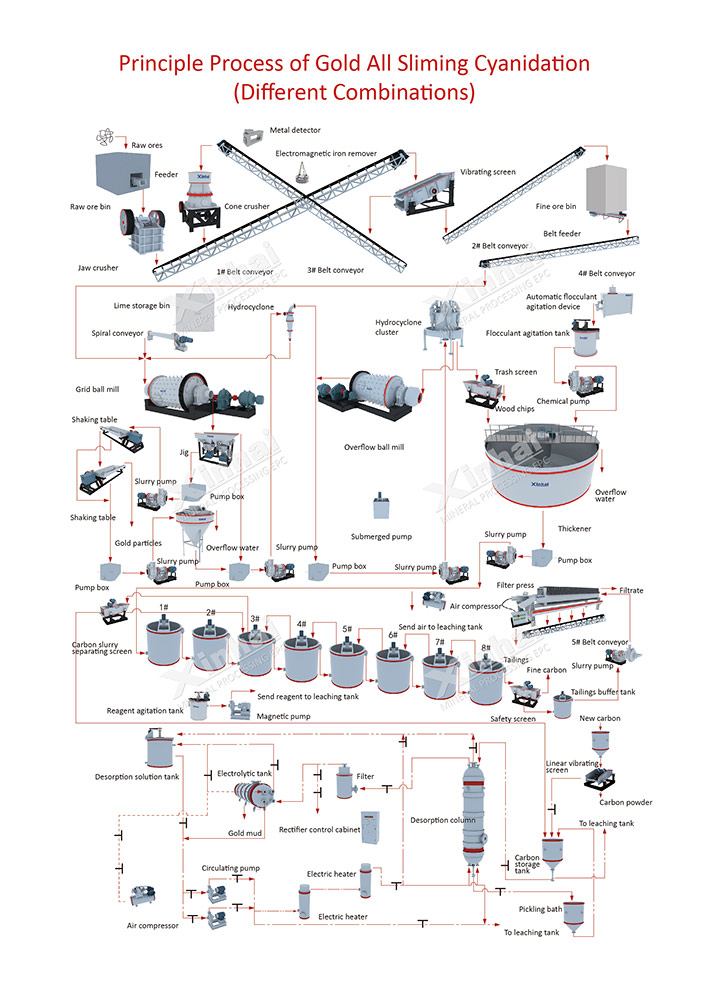

Gold carbon in leach(CIL) is a gold extraction process in which the two operations of cyanidation leaching and activated carbon adsorption of gold are partially or completely carried out at the same time. In view of the high cyanidation leaching rate at the initial stage of leaching and the gradual reduction of cyanidation leaching rate, most of the carbon in leach(CIL)processes currently used are the first tank is a simple cyanidation leaching tank, and each tank from the second tank is leaching and adsorption at the same time, and the pulp and activated carbon are countercurrent adsorption.

This process was successfully studied by mintek concentrator in South Africa on the basis of gold Carbon in Pulp(CIP) process in the 1980s.

Comparing the typical processes of CIL and CIP, it can be seen that the carbon slurry method is to adsorb dissolved gold and silver from the cyanide slurry in which gold and silver have been completely leached, while the carbon leaching method is to adsorb dissolved gold and silver while cyanide leaching. The raw material preparation, desorption of gold loaded carbon, regeneration of carbon, treatment of precious liquid and tail slurry and other operations of the process are basically the same. Activated carbon is used to adsorb dissolved gold and silver from the slurry, but the process is not completely the same, There are also obvious differences between the two processes.

The cyanidation leaching and carbon adsorption of carbon slurry method are carried out separately, so separate leaching and adsorption equipment need to be configured respectively. Moreover, the cyanidation leaching time is much longer than the adsorption time of carbon, the total time of leaching and adsorption is long, the capital investment is high, and the plant area is occupied. Due to the long production cycle, a large amount of gold and silver remained in the production process, and the backlog of funds was serious.

Comparing the typical processes of CIP and CIL, it can be seen that the CIP is to adsorb dissolved gold and silver from the cyanide slurry in which gold and silver have been completely leached, while the CIL is to adsorb dissolved gold and silver while cyanide leaching. The raw material preparation, desorption of gold loaded carbon, regeneration of carbon, treatment of precious liquid and tail slurry and other operations of the process are basically the same. Activated carbon is used to adsorb dissolved gold and silver from the slurry, but the process is not completely the same, There are also obvious differences between the two processes.

The cyanidation leaching and carbon adsorption of CIP are carried out separately, so separate leaching and adsorption equipment need to be configured respectively. Moreover, the cyanidation leaching time is much longer than the adsorption time of carbon, the total time of leaching and adsorption is long, the capital investment is high, and the plant area is occupied. Due to the long production cycle, a large amount of gold and silver remained in the production process, and the backlog of funds was serious.

The CIL combines leaching and adsorption, which keeps the gold content in the liquid phase of the pulp at the lowest level and is conducive to accelerating the cyanide leaching process of gold and silver. Therefore, the total operation time of the carbon leaching process is short, the production cycle is short, the capital investment and plant area are small, the amount of gold and silver retained in the production process is small, and the backlog of funds is light.

At the beginning of cyanide leaching, the leaching rate of gold and silver is high, and then the leaching rate gradually decreases, and the increased gradient of leaching rate decreases with time. Since the activated carbon can only adsorb the dissolved gold and silver from the pulp, in order to accelerate the cyanidation leaching of gold and silver, generally, 1 ~ 2 tanks are still set as the pre leaching tank before the carbon adsorption of the CIL process. Generally, the carbon leaching process is composed of 8 ~ 9 stirring tanks. The first 1 ~ 2 tanks are cyanidation pre leaching tanks, and the next 7 ~ 8 tanks are leaching adsorption tanks.

Compared with CIP process, CIL process uses more activated carbon, the contact time between activated carbon and pulp is longer, and the wear of carbon is larger. The amount of gold and silver lost in tail pulp with the wear of carbon is higher than CIP process.

The above introduces the difference between CIL and CIP process. The determination of gold ore dressing process needs to go through strict beneficiation tests and be determined by professionals. If there is a demand for gold ore dressing, please contact Xinhai.