Magnesite, a crucial mineral resource, finds widespread applications in metallurgy, construction materials, and chemical industries. The extraction of magnesite predominantly employs flotation methods, which separate magnesite from impurities, facilitating purification and enrichment. This article aims to elucidate the methods and process of magnesite flotation, encompassing key steps, equipment, and parameters involved.

1. Direct Flotation Method

The direct flotation method involves directly subjecting the ground ore slurry to flotation. It relies on the physical and chemical differences between magnesite and impurity minerals for separation. This method is straightforward and suitable for situations where magnesite and impurity minerals exhibit significant differences in density, particle size, surface properties, etc.

2. Reverse Flotation Method

The reverse flotation method entails pre-treating the ore slurry, followed by gravity separation to separate magnesite and some impurities. It enhances the magnesite grade and recovery further. This method is suitable for situations where magnesite and impurity minerals exhibit minor differences in density, particle size, surface properties, etc.

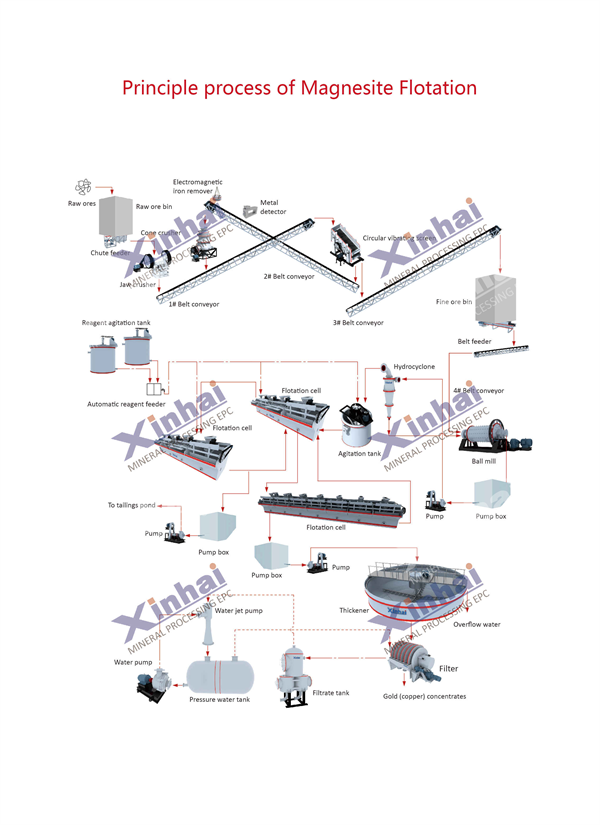

1. Ore Crushing and Grinding

The magnesite ore undergoes crushing and grinding to obtain an appropriate particle size for flotation. Crushing equipment such as jaw crushers and cone crushers, as well as grinding equipment like ball mills and ore mills, are commonly used for this purpose.

2. Preliminary Treatment

The ground ore slurry undergoes preliminary treatment to remove larger particles and heavier impurities. This step enhances the magnesite grade. Equipment such as heavy medium separators and spiral classifiers are employed for preliminary treatment and gravity separation.

3. Flotation Separation

The pre-treated ore slurry is subjected to flotation separation, where flotation agents and bubbles are utilized to further separate magnesite from impurities. Commonly used flotation agents include oxidants, coagulants, collectors, etc. Flotation conditions such as stirring speed, bubble size, reagent dosage, etc., are controlled to achieve effective separation.

4. Clean Recovery

After flotation separation, the collected magnesite flotation foam is cleaned and recovered. The cleaned concentrate can be utilized for subsequent processing and utilization.

5. Tailings Treatment

Tailings generated during the flotation process contain unrecovered impurities and some magnesite. Tailings treatment methods such as neutralization, precipitation, filtration, etc., are employed to meet environmental protection and resource utilization goals.

1. Crushing Equipment: Jaw crushers, cone crushers, etc.

2. Grinding Equipment: Ball mills, ore mills, etc.

3. Preliminary Treatment Equipment: Heavy medium separators, spiral classifiers, etc.

4. Flotation Equipment: Flotation machines, agitation tanks, etc.

5. Flotation Agents and Reagents: Oxidants, coagulants, collectors, etc.

Magnesite flotation is a vital mineral separation technique widely employed in magnesite extraction and processing. By selecting suitable flotation methods, process parameters, and equipment, efficient purification and enrichment of magnesite can be achieved, providing essential technical support for magnesite resource utilization and development.