Magnesite is a carbonate of magnesium, with the chemical formula of MgCO3. Magnesite resources are distributed intensively and the deposit is huge. Usually, the ore body is thick, buried shallow and easy to exploit. These magnesites have high grade, few impurities and high industrial utilization value. This article introduces the use of magnesite, the method of beneficiation and purification, and the process flow.

The industrial value of magnesium ore is mainly the magnesium oxide contained in it, which has high temperature fire resistance and cohesiveness, and can be used to extract magnesium metal. Therefore, it is widely used in metallurgy, building materials, chemical industry, light industry, agriculture and animal husbandry and other fields. The magnesite used in industry has a clear limit on impurities, so the mined high crystal magnesite ore can be directly used in application, but it can also be beneficiated before calcination.

In order to remove harmful impurities and improve the ore crystal grade, and solve the separation problem between silicate gangue mineral and magnesite, as well as magnesite and dolomite, the current industrial beneficiation and purification methods of magnesite mainly include flotation method, light burning method, thermal separation method, and gravity separation method, electric separation method, radiation separation method, magnetic seed separation method, etc.

Flotation is a method of separating magnesite and silicate minerals by making use of the difference in their surface physical and chemical properties.

Flotation is one of the main purification methods for treating magnesite. For gangue minerals such as talc and quartz, which are mainly silicate minerals, good results can be achieved by adding amine cationic collectors and foaming agents under the natural pH value of the pulp during flotation, and the purity of magnesite can be increased to 95%~97%.

The flotation of magnesite generally adopts the principle process of reverse positive flotation, that is, first remove silicate gangue minerals (such as quartz, serpentine, talc, etc.) through reverse flotation, and then use fatty acid collectors and effective inhibitors to suppress other gangue minerals in alkaline pulp to positively float magnesite.

The positive flotation of magnesite should be carried out under alkaline conditions. The addition of sodium silicate and sodium hexametaphosphate can selectively partially inhibit calcium containing minerals such as dolomite.

Magnesite calcined at 750~1100 ℃ is called light burned, and its product is called light burned magnesium powder. Since the burning loss of magnesite is generally about 50%, the MgO content in the ore can be almost doubled by light burning. In this sense, light burning is the most effective means of MgO enrichment. In addition, light burning is also a preparatory operation for thermal separation and some gravity separation of magnesite. Light burned magnesium has high activity and is an ideal raw material for producing high density magnesia.

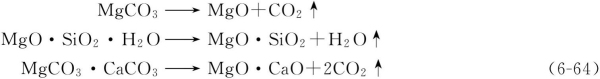

"Thermal separation" is to separate the high silicon magnesite ore by using the difference in thermal properties between the main impurities of talc or dolomite, chlorite and magnesite. During calcination, magnesite and silicate gangue minerals are decomposed respectively according to the following formula:

The decomposed light burned magnesium is brittle, soft and fragile, while the gangue mineral talc becomes hard with the increase of temperature. The hardness difference and density difference between the two are used for selective crushing, screening and air separation, so as to separate magnesite from other minerals.

The process flow of carbonization method is: calcine magnesite to decompose it into MgO, wet grind the light burned MgO, and during the grinding process, MgO reacts with water to generate insoluble magnesium hydroxide Mg (OH) 2. Put the slurry after grinding into the pressure reactor, adjust the liquid-solid ratio, inject CO2 and control a certain temperature, time and CO2 pressure to make Mg (OH) 2 change into soluble magnesium bicarbonate, namely Mg (HCO3) 2. After the carbonized slurry is clarified, filtered and washed, the filtrate is heated to escape CO2, and then basic magnesium carbonate is separated. Then calcine the basic magnesium carbonate to obtain high-purity magnesium oxide.

The beneficiation process of magnesite is as follows: after crushing and screening, the magnesite is fed to the ball mill for grinding, and the slurry after grinding is obtained from magnesite concentrate, middling and tailings after reverse flotation (one roughing and one scavenging) and positive flotation (one roughing and one cleaning). The final magnesite concentrate is obtained after dehydration and filtration.

The above are currently commonly used magnesite beneficiation and purification methods and processes. With the continuous progress of mineral processing technology and the renewal and iteration of mineral processing equipment, the mineral processing industry today has changed from the past. Intelligent, scientific and automated concentrators have been built one by one. Xinhai is always committed to providing customers with scientific and advanced beneficiation technology and equipment. If you need to beneficiate magnesite, please contact Xinhai!