Carbon slurry gold extraction is a gold extraction process that uses activated carbon to directly extract dissolved gold from gold bearing pulp.

.jpg)

Compared with the conventional process of continuous countercurrent decantation washing (CCD), the most important advantage of carbon slurry method is that it eliminates the washing of pulp and solid-liquid separation, and directly uses granular activated carbon to adsorb gold from pulp to replace the washing of leaching pulp, solid-liquid separation and clarification, degassing and zinc replacement of leaching solution. It simplifies the industrial production process, significantly improves the efficiency, greatly reduces the investment in equipment and infrastructure, and reduces the production cost. Under normal circumstances, using carbon slurry method can save investment by 25% - 50% and reduce production cost by 5% - 35%.

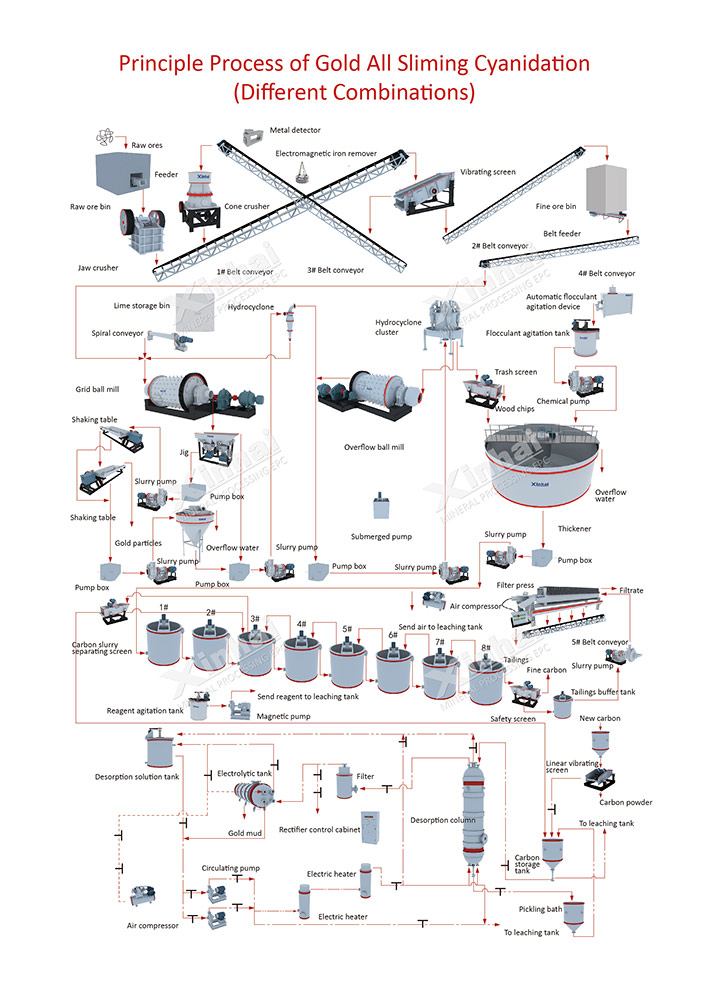

The cyanidation carbon slurry gold extraction process mainly includes raw material preparation, cyanidation agitation leaching, activated carbon countercurrent adsorption, gold loaded carbon desorption, precious liquid electrowinning, smelting ingots and activated carbon regeneration.

Gold bearing mineral raw materials are crushed, grinded and graded to obtain pulp with required concentration and fineness. In case of full slime cyanidation, the overflow of this classification can be sent for cyanidation leaching after concentration. When the gold bearing minerals are enriched by flotation before cyanide leaching, the graded overflow is sent to the flotation operation to produce gold concentrate. After the gold concentrate is grinded to the required fineness, the graded overflow is screened to remove ore sand and sawdust greater than 0.589mm, and then after concentration and dehydration, the slurry with a concentration of about 45% is sent to agitation Cyanidation for leaching.

Agitation cyanidation leaching is carried out in 12 series aerated mechanical agitation tanks. The underflow of the thickener first enters the slurry mixing tank, and the pulp is stirred with air and lime milk for several hours in advance to adjust the pH value and oxygen content of the pulp, and then enters the cyanide leaching circuit. While the pulp is stirred and leached, it is still necessary to add lime milk and cyanide, and blow in air to maintain the pH value and cyanide content of the pulp at the specified value. The specific operation is the same as that of stirred cyanide leaching, in order to obtain the highest possible gold leaching rate.

The slurry after agitation cyanidation leaching enters the activated carbon slurry countercurrent adsorption circuit. The adsorption system is generally composed of 4 ~ 6 activated carbon adsorption tanks, which realize the countercurrent flow of pulp and activated carbon through air lifter and inter tank screen. At this time, air can still be blown in to add lime milk and cyanide, but the last 1 ~ 2 adsorption tanks do not add cyanide to reduce the cyanide content in the depleted pulp. In the early stage of carbon slurry process, the vibrating screen is mainly used for the inter trough screen, which has a large amount of carbon wear. At present, the fixed peripheral screen, bridge screen or immersion screen are mainly used for the inter tank screen of carbon slurry process. The screened pulp is returned to this tank, and the activated carbon is sent to the previous tank. Regenerated carbon or new carbon is added to the last tank of the adsorption tank, and the gold loaded carbon is regularly transferred from the first adsorption tank to the gold loaded carbon desorption system for gold desorption and activated carbon regeneration. After the residual tail slurry is checked and screened (the sieve hole is 0.701mm), the leaked gold loaded fine carbon is recovered and sent to the tail slurry treatment process.

.jpg)

After removing sawdust and slime, the gold loaded carbon is sent to the desorption column for gold and silver desorption. At present, there are four methods for desorption of gold loaded carbon in production. They are zadera method, organic solvent method, high pressure method and South Africa Anglo American company law (a.r.r.l method).

The precious liquid obtained by desorption of gold loaded carbon is sent to electrowinning gold precipitation or zinc powder replacement gold precipitation, and the activated carbon is sent to carbon regeneration.

In the process of carbon slurry adsorption, in addition to adsorbing dissolved gold, activated carbon also adsorbs various inorganic and organic substances, which cannot be removed in the process of gold desorption, causing carbon pollution and reducing its adsorption activity. Therefore, the desorption carbon must be regenerated before returning to the adsorption system to restore its adsorption activity to dissolved gold. The regeneration methods of desorption carbon are acid washing and thermal activation regeneration.