Xinhai provides Low-voltage electrical equipment complete sets of power distribution cabinet design, production, installation and commissioning as one of the power distribution cabinet engineering services. XInhai already passed ISO9001:2015 quality management system certification. Multiple products passed CCC identification.

Complete electronic control system of equipment is mainly the electronic control system for processing plant, which pushes the application of intellectualization and integration of equipment, and the internet of things.

Unattended ground pound system in the whole process of weighing measurement data can be automatically collected, automatic discrimination, automatic command, automatic processing, greatly reducing the drawbacks of manual operation and work intensity. Using a card system, infrared monitoring anti-cheating, intelligent gates, video surveillance capture, voice broadcast reminder, LED large screen display, etc., with intelligent weighing software to realize unattended pound room.

Intelligent weighting metering system can carry out dynamic continuous weighing during the period ores or concentrates transportation on belt conveyor. At the same time, the transport flow is adjusted to achieve an accurate weight ratio. The automatic dosing system controls the instantaneous flow and cumulative amount of various materials according to the set ratio, thus meeting the quality requirements of controlling the final mixed product. It improves the quality and output of ingredients and production efficiency, and also reduces the working strength of labors.

The video surveillance and large-screen display system are the auxiliary tools of automated system and production scheduling management. It can make centralized control and unattended operation work better. At the same time, it provides a better safety guarantee for personnel, equipment and factory materials.

The automatic system of filling mainly includes automatic pulping control, filling flow control, filling contrite control, automatic ashing control, liquid level control of agitating tank, and one-key chain start parking.

The automatic system of filling mainly includes automatic pulping control, filling flow control, filling contrite control, automatic ashing control, liquid level control of agitating tank, and one-key chain start parking.

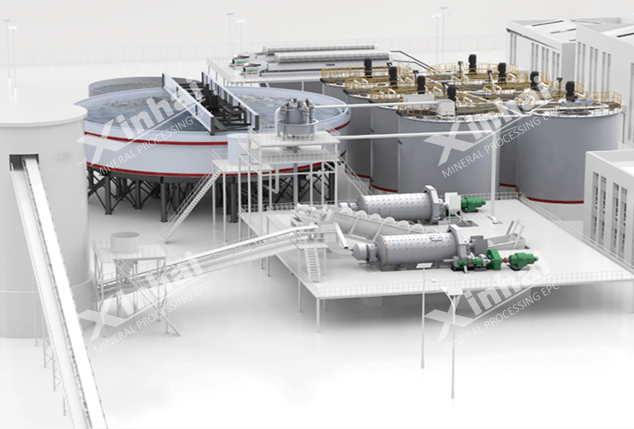

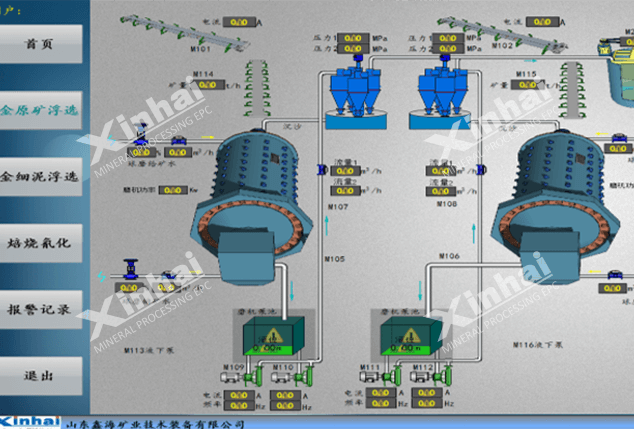

Mineral processing whole process automation system is a collaborative optimization control system for crushing, grinding, processing, concentrates dewatering.

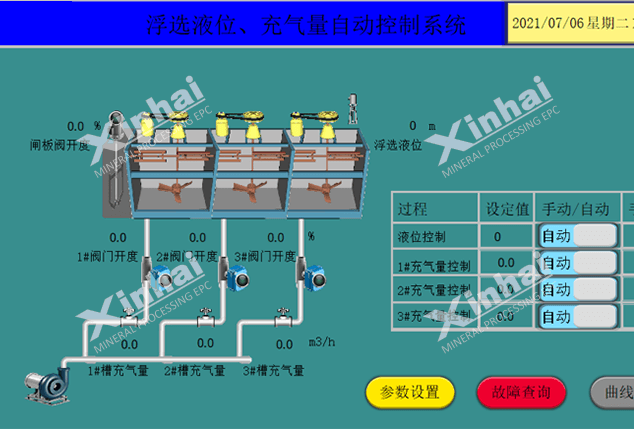

Flotation liquid control system mainly includes liquid level measure device, pneumatic or electric actuator, intelligent controller. The air volume adjustment mainly includes air flowmeter and motor regulated valve. Through accurate real-time detection and control, the flotation efficiency can be effectively improved, which play an important role in flotation process.

Grinding and classification automated system is automatic controlled. Through the comprehensive analysis and judgement of grinding equipment load, feeding characteristics and other factors, realizing the optimizing controlling of feeding amount, grinding concentrating, classification overflow concentration and fineness. At the same time, the automated system also realizes the automatic parameter detection, displaying, various fault alarms. Finally, keep the grinding and classification running under a good situation.

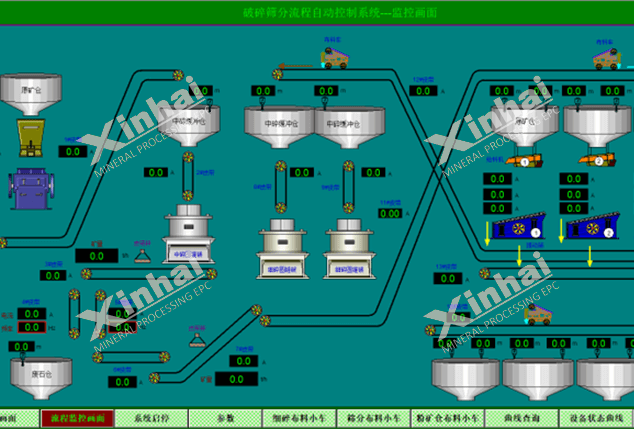

Curshing and screening automatic system uses PLC controlling system to detect the material level and rate of work. Judging the load of crusher and optimizing feeding amount. Adjusting the speed to the mine makes the crusher run at near full load.

Automatic material distribution is an automatic distribution device (or distribution method). It realizes automatic materials distribution. The material distribution is more evenly. It also avoids the accidents such as bunker emptying or ore crushing. The automatic material distribution devices mainly include feed bin, material level detection device for silo, belt conveyor, discharge cart, discharger positioning device, etc.

A reagent feeder with excellent structure and advanced technology

A stable and continuous flocculants powder feeding device in preparation of flocculants solution

An automatic sampler for pulp sampling from closed pipelines

A weighting equipment for metering belt conveying capacity with simple structure and advanced technology