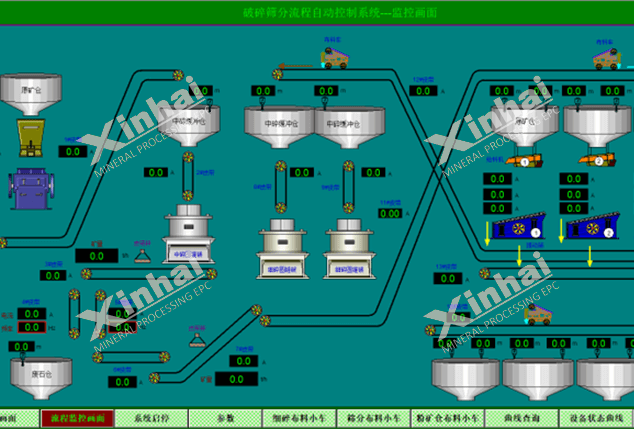

[Introduction]: Curshing and screening automatic system uses PLC controlling system to detect the material level and rate of work. Judging the load of crusher and optimizing feeding amount. Adjusting the speed to the mine makes the crusher run at near full load.

[Capacity]:

[Improvement]:

The critical signal covers the all theequipment in flow, realizing no dead ends real-time monitoring;

Interlock protection, equipment inspectionprotection, in-time early-warning. The point of failure is precisely located;

Alarm before starting. System automaticjudge whether the starting conditions are provided with. It guarantees thesafety of operation and production.

Multiple operation methods: local operation/remotemanual operation/remote automatic operation, satisfying multiple usingrequirements;

The types of instruments and PLC satisfiesthe requirement of using in dust environment, stable and reliable.

Realizing unattended position, based oninspection. Improving working environment and personnel security;

Remote operationshortcut/convenient/reliable. Compared with traditional manual operation, theproduction efficiency is advanced;

Equipment operating situation real-timemonitoring and alarming, reducing the failure rate of equipment;

High degree in intelligentization andinfotmatization, providing multiple types of report forms of equipment andproduction.