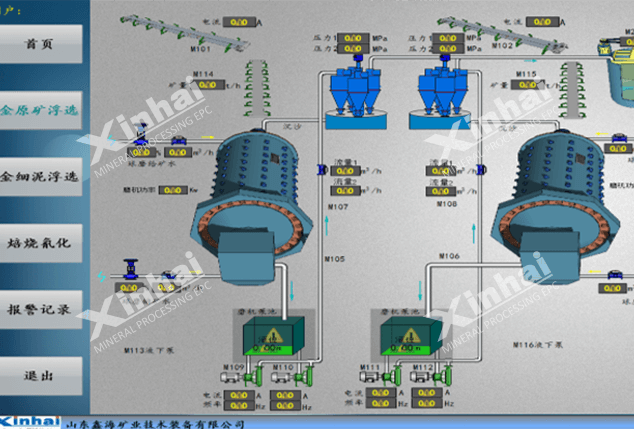

[Introduction]: Grinding and classification automated system is automatic controlled. Through the comprehensive analysis and judgement of grinding equipment load, feeding characteristics and other factors, realizing the optimizing controlling of feeding amount, grinding concentrating, classification overflow concentration and fineness. At the same time, the automated system also realizes the automatic parameter detection, displaying, various fault alarms. Finally, keep the grinding and classification running under a good situation.

[Capacity]:

[Improvement]:

Ball mill automatic feeding controlling,the feeding outlet plugging automatic detection and switchover;

Grinding concentration automatic adjusting,water amount automatically overcoming water pressure fluctuations;

Cyclone feeding concentration automaticadjusting, guaranteeing the classification effect;

Automatic ball adding machine realizessteel ball automatic uniform ratio adding, real-time monitoring of runningstate, and accident alarming;

Combining with the grinding audio spectrumanalyzer and online granularity analyzer, build grinding closed-circuitoptimization adjusting system, improving grinding efficiency and productionquality.

Realizing unattended position, focus onpatrol;

Stable production flow, balancing workingcapacity and efficiency;

Guaranteeing the indexes of grinding andclassification and improving the desk-time processing capacity;

Production data generate multiple reportqueries to optimize production scheduling.