[Introduction]: A wet autogenous grinding mill that materials as grinding media

[Capacity]: 200-350mm

[Improvement]: High-efficiency autogenous mill can realize the second and third stage crushing and screening, and part or all of crushing and grinding functions of the rod mill and ball mill.

Simplify the crushing and grinding process;

Low energy consumption, no dust pollution, less auxiliary equipment, simple production automation, anduniform particle size.

Feed particle size is 300-400 mm, and after the first autogenous grinding, the output product is below 0.1 mm;

Autogenous mill is suitable for ore with a high content of mud and water; small floor space, low investment.

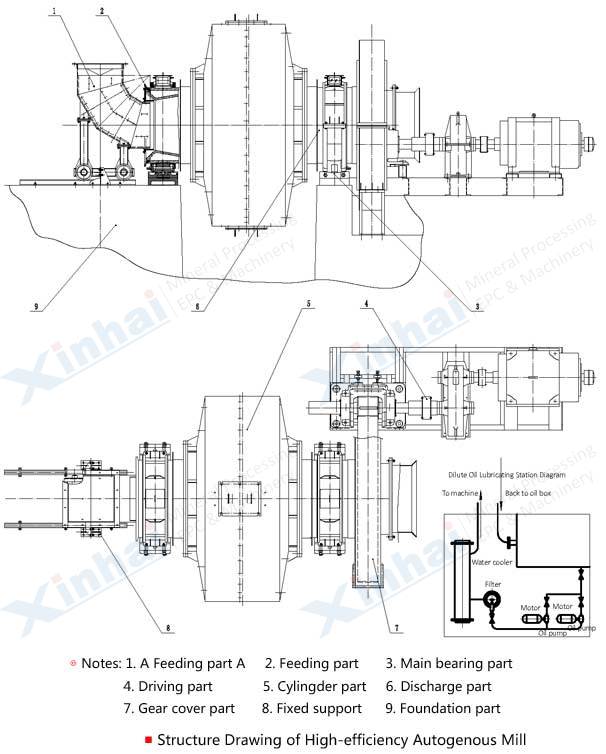

The working principle of the autogenous mill is almost the same as that of the ball mill. The difference is that the barrel body of the autogenous mill is larger, which does not use steel balls or any other grinding medium. The efficient autogenous mill uses the crushed material in the barrel body as the grinding medium, which continuously impacts and grinding to achieve the purpose of grinding.

Sometimes, in order to improve the processing capacity of the autogenous mill, a small number of steel balls can be appropriately added, usually accounting for 2-3% of the effective volume of the autogenous mill (also known as a semi-autogenous mill).

| Model | Diameter (mm) | Length (mm) | Feed Size (mm) | Main Motor | |||

| Model | Power (kW) | Voltage (V) | Weight (t) | ||||

| ZMJ4014 | 4000 | 1400 | < 350 | JR148-8 | 245 | 10000 | 75 |

| ZMJ4018 | 4000 | 1800 | < 350 | JR1410-8 | 320 | 10000 | 82 |

| ZMJ5518 | 5500 | 1800 | < 400 | TDMK800-36 | 800 | 10000 | 175 |

| ZMJ6522 | 6500 | 2200 | < 400 | TDMK1600-40 | 1600 | 10000 | 280 |

| ZMJ7525 | 7500 | 2500 | < 400 | TM2500-16 | 2500 | 10000 | 455 |

| ZMJ7528 | 7500 | 2800 | < 400 | TM2500-16 | 2500 | 10000 | 465 |